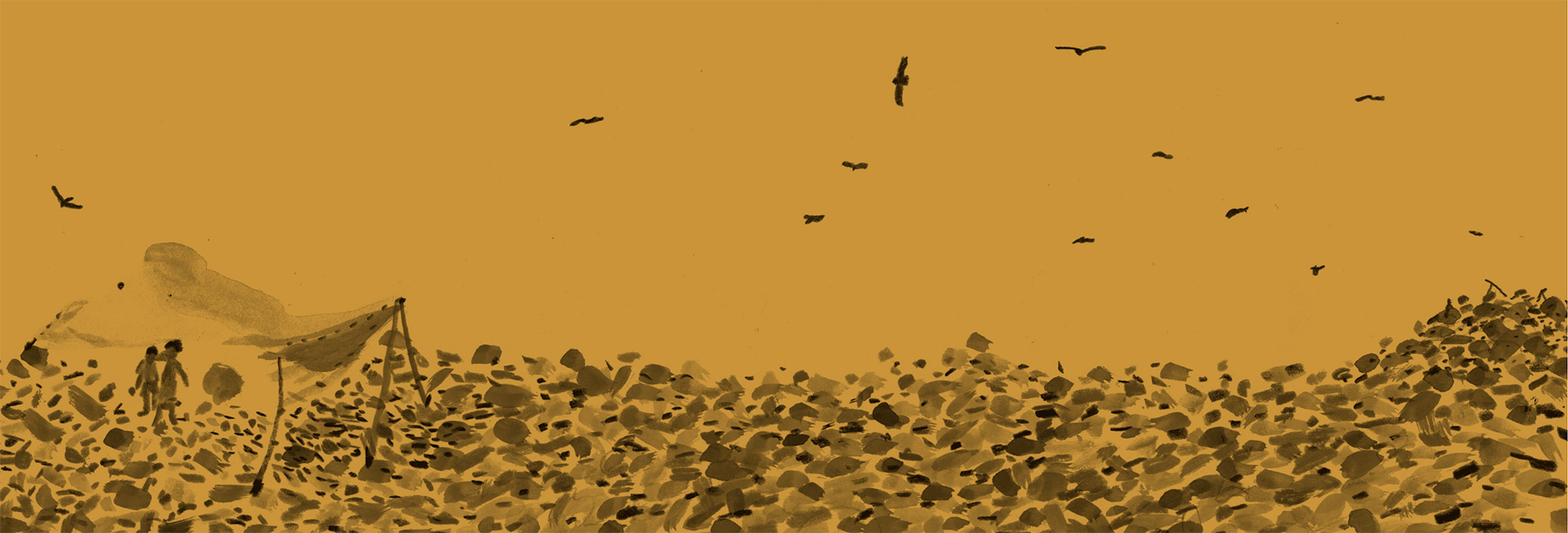

ESSAY AND ILLUSTRATIONS BY PETER WIEBEN

There

are many men there, thousands of them. The men are crawling all over the ships.

The ships have been pulled out of the water using big winches that are sunk

into the sand on the beach. They pull the ships up onto shore, then the men are

released to swarm them. They cut them to pieces with oxygen torches and

acetylene torches. The pieces they cut fall off and are very large. Sometimes,

the slices come from the front of the ship, like bread slices. Other times, the

slices come from the sides, like turkey slices. Either way, they must be picked

apart.

The

fat man, the owner of lot 161, told us that five men die in Alang each year.

Will sensed that he was lying, and I did, too. Will told me that one reason the

number of deaths is higher than five is because there are no masks or filters

in the shipbreaking yard. Whatever comes out of the ship, if it is not scrap

metal or something usable (like a lifejacket), is set on fire.

Sometimes

an oil tanker arrives. In these cases, the tanker is cut open on shore and the

oil spills out. That is why the Alang coast is brown. I thought that anyway,

but Will told me that the coast is always brown in India, not just in Alang. I

walked down to the mud and smelled it. It smelled like shit. Will told me that

is because the workers do not have any plumbing in their homes. The homes for

the workers at Alang are made of plastic sheets and scraps of wood and tarps

and so on. When they need to use the bathroom, they wander out into the ocean.

Will

is a factory worker from Tulsa, Oklahoma. For this reason, he was more adjusted

to the environment of the Alang ship-breaking yard. The smoke, combined with

the chemicals, the exhaust of the machines, and the stinking ocean made it so I

hated my own breathing. Will said that was normal.

I

saw a worker there and I told Will that he couldn’t be older than 15. Will said

that was bad. But then he told me that he started work in a foundry when he was

17. It wasn’t good, he said, but he really couldn’t judge.

I

asked Will if he thought human rights abuses were happening in the shipyard in

Alang. I told him that I had read in many newspapers that these ship-breaking

yards were the scene of human rights abuses. In fact, I believed that I had

seen some with my own eyes. Will said he didn’t really think so. He said the

pay was better here than in many parts of India. Besides, he said, the

conditions were not that much worse here than in the average factory. The

reason the shipyards were big news was because Westerners felt guilty that

their ships were being broken up here.

We

sat with the owner of lot 161. His face was round and so pudgy that his eyes

were really squinty and gangster-looking. I do not know if he was actually

evil, though. The fat man was wearing a gold watch and had tea delivered to us.

I did not take any. I told the fat man’s assistant that I was sick to my

stomach. The assistant became afraid of angering the fat man, who rarely hosted

foreign dignitaries such as ourselves. Foreigners tended to leave and say nasty

things about the operation there. Foreigners were obsessed with Alang, the fat

man said, because they did not understand it.

Nowadays,

the value of a big ship is only determined by its weight. The human labor and

knowledge and design and so on are negligible to the price. That is how cheap

human labor has become. This is something the fat man explained to me.

Nowadays, things like ships are measured by the kilo.

The

ships are bought as-is. The beds, the maps, the lockers, the exercise

equipment, ropes, lifeboats, blenders, spoons, and so on are all still there.

Outside Alang, there are open lots or rudimentary warehouses holding all of

these things for sale. I saw a whole warehouse full of treadmills. Another was

just couches. It was really amazing. All of these things were along one long

road leading to the ships themselves and the brown beach. I measured the

distance from one end of this road to the other, and the distance was six

kilometers. On both sides of that road were continuous piles of ship stuff that

reach higher than a house. I probably saw over one thousand blenders.

The

ships’ ballasts, giant redwood trunks made of forged steel, are taken away to

be turned on lathes for weeks, making them into molds for the pipes that run

beneath our cities. Then the molds are brought to factories and filled with

liquid steel. Then more cities are built. And ships are made to supply them

with all the things they need.

Will

is an engineer and he is pretty good at math and at figuring things out. I

asked him after I returned from India: If you stacked up all humans on a scale,

and then all machines, which one would be heavier?

“There

are about 6 billion humans at about 60 kilos average,” Will wrote to me.

“That’s 0.36 gigatons.”

He

wrote: “The total number of cars produced last year was 80 million. And the

total number in existence is now more than a billion. The average car weighs

more than 1.5t. This means that cars alone outweigh humans by four times: 1.5

gigatons of cars vs 0.36 gt of humans.”

I

used to have this nightmare where I found myself standing inside of a giant

mouth. The mouth was as big as the universe and was lined with sharp teeth

pointing downwards. I am holding onto a tooth and all around me, human bodies

are falling down into the mouth. Millions of them, people from all over the

world. I told Will that was kind of the feeling I got when I was in Alang—that

we were all falling down into some kind of abyss, and that it was completely

out of our control to stop it. That it wasn’t progress that was moving us, but

gravity. I told him I needed a bit of time off from looking at machines.

Will

and the German intern said that it was not a humanitarian problem or an

environmental problem. They said that like all problems, it was an engineering

problem. The solution to all of these machines, they kept insisting, was more machines.

I

told them that I thought they were maniacs.

“Listen,”

Will said. “I’ll draw it out.”

He

proceeded to redesign Alang with locks for raising the ships and for holding in

spilled oil. There were big cranes to hold up the ships and the ship pieces so

they wouldn’t fall and crush the workers. He put robotic torches on robotic

cars on these same cranes to do the heavy cutting. He said that humans would

only have to push the buttons. It could be a good operation, he said. Clean and

efficient and humane. It would even be cheaper. More profitable.

I

looked at his drawing and I had to admit that it seemed like a very good idea.

Much better than now.

“So

why don’t they do it?” I asked.

“Folks

are just too busy whipping their workers to think about the numbers,” Will

said. “Quite common.”

Source:

In These 24 March 2016

No comments:

Post a Comment