|

The 10 men heave a sigh of relief. Had

they failed, the next opportunity would have come after 15-20 days.

|

It is 1.30 am on a cool November night and the tide is

high. Around 10 men get into position at Lakribunder Plot No. 10 at Darukhana.

A hand signal later, three winch machines roar to life, yanking two-inch thick

iron chains through the soft sea mud. They are attempting to move a

69-year-old, 704-ft-long, 21,067-tonne object closer to land. An hour later,

INS Vikrant has moved 4 feet.

The 10 men heave a sigh of relief. Had they failed, the

next opportunity would have come after 15-20 days. “Our work revolves around

amavas (new moon) and bahaav (tide),” says a worker.

The Majestic-class aircraft carrier, the only such warship

in the world still available of the original six constructed during Second

World War — all of them since scrapped — is being torn down at Mumbai harbour.

Its bow already gone, Vikrant looks naked. Vulnerable. Exposed.

|

The cutters and segregators at work on

the site. Behind them are the containers with scrap already loaded.

|

The last time the ‘Old Lady’ felt this

vulnerable was back in 1971. The war was on, and Pakistan submarine Ghazi and

the Pakistani Air Force were on her tail on the Eastern Front. “The Indian Air

Force then attacked the Pakistani Air Force base. When Ghazi was sunk, Vikrant

had a free run of the Bay of Bengal,” says a Naval officer, who served on board

the carrier.

Its crew eventually won two Mahavir Chakras and 12 Vir Chakras for

their war efforts. “Vikrant helped shorten the 1971 war and saved lives,” says

I C Rao, vice-admiral (retd), who served onboard as a chief engineer in

1975-76. “She was the only aircraft carrier east of the Suez Canal, with the

exception of the one with Australia.”

|

Workers smelting the inside of the

ship. They are being extra careful to rule out the presence of petrol, used on

Vikrant

|

It served for 26 more years, before

being decommissioned in 1997. On November 20, 2014, though, as the beginning of

the end started for INS Vikrant, there were few from those days present to give

her company.

It will take 200 men six months, working 16 hours a day on an

average, to cut up the ship and sort what’s retrieved from it to be re-used or

sold as scrap. Every day, around 100 tonnes are being cut from the ship,

translating into 50-80 tonnes of useable scrap.

At the end of the exercise, new

owner IB Commercial Pvt Ltd, which bought the ship from the Navy for Rs 63.02

crore, will earn at least Rs 100 crore as scrap. For the Mumbai Port Trust

(MbPT) too, history is being made. Vikrant is the biggest ship and the first

Naval one to be broken at the harbour, where shipbreaking began in the 1950s.

It is docked at the largest of its 18 plots, spread over 3,000 sq m. The ship

is stuck about 5 metres deep in the wet soil, making it harder to pull. At

present, eight other ships are being broken down at Darukhana. Vikrant easily

towers over them.

*** Hariram Yadav, 58, oversees the work force of cutters,

segregators, crane and winch operators. He is in charge of cutting up Vikrant,

breaking its large chunks into smaller pieces, as well as segregating the scrap

into rollable sheets, ferrous material, non-ferrous material and unusable junk.

His men have with them around 100 cutters, welding machines, oxygen tanks,

cylinders and metal content testers. Yadav, a contractor hired by IB

Commercial, was himself part of the operations to pull the ship closer to

harbour. “Double zor lagana padta hai kheenchne mein (I have to put in twice

the effort to pull the ship),” he says.

|

The bow area falling off after 72

hours of trying to separate it. An important component, it was built to

withstand collisions

|

At 14,085 metric light displacement

tonnes (LDT) — the weight of a ship without anything on board, used to

determine the value of its scrap — Vikrant is much heavier than regular

merchant ships, some of which weigh in at around 8,000 LDT. While those have

large cargo sections and regular steel fittings, Vikrant has cabin rooms,

hangars large enough to keep up to 21 aircraft, armament storage areas and is

made of gun metal, a type of alloy heavier than steel. At 2.30 pm, on November

20, the breaking began from inside. Around 20 workers entered from the opening

on the bow of the ship, from where the anchor comes out, to begin smelting her.

They started with the 120-ft ramp, cutting off 10 ft, and moved on to the front

of the ship, followed by the cable deck. In 72 hours, the bow was brought down.

The workers had to made sure the fuel pipeline of the ship was clean before

they began smelting. “Unlike other ships that have oil, Vikrant used petrol.

Even kachra will burn if petrol is left, so we have to be very careful,” says

Ram Yadav, 42, one of the cutters. That’s what makes cutting this ship

different from other ships, he adds. Pointing at the broken part from a

distance, vice-admiral (retd) Rao says the bow is perhaps the most important

part of a ship such as Vikrant.

With its watertight compartments, it was built

to withstand a collision, keeping the rest of the ship intact. “See the

protruding parts on the sides, that’s where the anti-aircraft guns, 40-mm

short-range ones, were positioned. Further ahead, there were three large

hangars, where aircraft were stored and serviced,” he continues. A week into

the breaking process, around 500 tonnes of scrap have been removed from

Vikrant. Washbasins and broken cabin rooms, frames of the bulkhead and the

anchor winch peek out. Cutters first mark a part of the ship and begin melting

the edges along it.

A winch then tugs on the hook attached to the marked

portion to remove it, cranes lift the part to a separate area, where it is

further cut. Scrap is loaded onto containers at the plot itself. As on Thursday

last week, five containers were half full. None of the scrap has been sold so

far. With expensive non-ferrous and ferrous pieces kept in the open, security

guards keep vigil day and night to prevent stealing, including from sea.

***

The workers will move next towards the stern (end of the ship), parts of flight

deck, the bridge, the operations room, the flying control panel, the mess

decks, the engine room and the keel. IB Commercial Director Abdul Karim Jaka

explains the process. Unlike the Alang ship recycling ward in Gujarat —the

largest in the country — Jaka says, at Mumbai, the soil at the shipbreaking

yard is marshy and the ships tend to sink into the mud.

|

Work on to break the 120-ft ramp

inside the ship. By the end of the week, only 10 ft had come off

|

“It takes longer to break a ship in

Mumbai. We have to break it linearly —cutting an upper portion, pulling the

remaining part of the ship closer to land and then cutting below the

waterline,” Jaka says. There is no fixed schedule, the cutting decided by tides

and whether a particular part is cut or not. Alang has hard mud. The ships

there can be broken from many points simultaneously as they do not sink into

the soil. But Jaka couldn’t have moved Vikrant to Alang. Given its damaged

hull, the ship wouldn’t have survived the journey. Jaka’s firm is involved in

shipbreaking at both yards, but this is his first time with a Naval ship and he

is restless to get to its engine room.

“That’s the best part of this ship,” he

beams, referring to the part of the ship that will supply him the largest

amount of non-ferrous material. The engine room is approximately 400 ft from

the bow portion. As per rough estimates, non-ferrous parts will fetch Jaka Rs

100-250/kg, while ferrous parts will fetch him Rs 25-28/kg.

“Compared to other

ships, this ship will give us non-ferrous content of a better quality,” he

says. “Baki toh asmaani sultani hai (The rest is God’s wish).” Naval vessels

always have more non-ferrous content, Jaka adds. “The Navy does not compromise

on quality.” Jaka says he deserves whatever he can make from the ship given

that it took him almost a year since buying Vikrant to start breaking it. He

doesn’t know much about its history except that it was deployed in the 1971

war. “It helped us win. The warship made us proud.”

*** It was in November 2013

that the Jaka family first saw a sale notice for the Vikrant. However, the

auction was postponed because of a PIL seeking to stop the ship from becoming

scrap. After the Bombay High Court dismissed the PIL on January 23 this year,

bids were refloated and IB Commercial won in an online auction. The Navy

confirmed the sale in April and IB Commercial made arrangements to tow the ship

towards Darukhana starting May 15, when the tide would have been high and

conditions favourable. But on May 5, another petition was filed before the

Supreme Court. The latter gave an order maintaining status quo. Worried over

the piling interest on his loan, Jaka wrote to the Navy saying he wanted to

back out of the deal. Return the Rs 63.02 crore and keep the deposit till the

case is resolved, he told the Navy. The Navy finally informed the Supreme Court

that attempts to find bidders to turn Vikrant into a museum had failed and that

it had been found to be unsafe.

A Board of Specialist Officers constituted in

early 2012 estimated the float worthiness of the ship to be a few months and

said that any damage would result in free flooding of the ship. “It was time for,

considering the deteriorated material state of the ship, insulation of electric

wiring and systems, inadequate fire fighting and damage control facility on

board, keeping the ship alongside any longer would expose her.

The hull of the

69-year-old ship has become so weak that even cadets cannot go on-board for

training purposes,” the HC order quoted the Navy as saying.

Another aircraft

carrier inducted into the Navy also required the berth occupied by Vikrant in

the Naval dockyard in Mumbai, it added. Sensing the danger the coming monsoon

in Mumbai posed to the ship, the vacation bench of the Supreme Court allowed IB

Commercial to tow the ship to near Lakribunder at Darukhana. IB Commercial

began seeking permission for shipbreaking from MbPT, the Maharashtra Pollution

Control Board and Customs officials.

Six months later, the shipbreaking began.

“My experience will be a lesson for other shipbreakers who buy Naval ships.

Emotions run high and shipbreaking gets delayed. I will not buy another Naval

ship,” says Jaka. “Also, it is quite expensive to break ships in Mumbai.”

***

MbPT only issues leases for a maximum of three months, at a cost of Rs 1.25

lakh per day in case of Vikrant. At Alang, shipbreaking firms can buy a plot on

a long lease and cut multiple ships simultaneously. Apart from the high costs,

a 3 per cent octroi is levied for shipbreaking in Mumbai, making the industry

unviable, adds Sanjay Gupta, member of the Iron Steel Scrap & Shipbreakers

Association of India.

“Ship prices worldwide are high and have not fallen,

while the demand and prices of steel have gone down,” he adds. The golden

period for ship recycling was 2009, Gupta says, as the international freight

market had crashed following the bankruptcy of Lehman Brothers. “Now the

industry is hit by falling rupee and the slowdown in the construction business.

There is no demand for finished product, hitting the recyclable steel industry

hard. The future looks bleak too,” he says.

Workers operate under largely

unsafe conditions at the port. While some cutters still wear helmets and

gloves, most choose to do without any gear despite possible exposure to harmful

substances. Metal shards, oil, flammable oxygen tanks and cylinders surround

them, while the firefighting equipment is outdated. The burning sun and humid

sea breeze, even in November, also make working tough. The men, mostly from

Uttar Pradesh, Bihar, Assam and West Bengal, work continuously from 8 am to 6

pm with just an hour’s break for lunch, for daily wages of Rs 350. For the

duration of this job, they are staying in rooms at Kolsa Bunder, 300 metres

away.

This is the only work that most of the workers know. And most are

oblivious and disinterested in the warship’s glorious history.

The only ones to

shed a tear for INS Vikrant or to try record its final moments, in fact, are

former or retired Navy officials. While some regularly come to take

photographs, they also keep their distance.

“It is a national shame that we

could not save an iconic ship like her. We sold our nation’s pride for a mere

Rs 60 crore. Watching her being broken is like seeing our own house being

brought down. I blame lack of public spirit and misgovernance by the state and

Centre,” says Rao, adding, “She who once controlled the sea and ended a war is

now part of the scrap world.”

‘The Old Lady’

Nicknamed ‘The Mother’ by

aviators, Vikrant was built in 1945 in Britain as part of WWII effort and

commissioned in the British Royal Navy as HMS Hercules (the HMS standing for

Her Majesty’s Ship). However, the war came to an end before she could be

pressed into service and HMS Hercules was “mothballed”. “Lord Mountbatten was

instrumental in getting her to India. The deal was signed in 1957. With

Vikrant, the Indian Navy came of age,” says an officer.

The ship joined the

Indian Navy in 1961. It was India’s first aircraft carrier, at a time when

India had only frigates, destroyers and other surface ships. Its initial air

wing consisted of British Sea Hawk fighters and French Alize anti-submarine

aircraft, later followed by Sea Kings and Chetaks.

|

The Vikrant in her heydays

|

She was also witness to the first ever

successful underwater ejection in the Navy — the world, some claim —when

Commander Peter Debras whose aircraft had fallen into the sea managed to eject

from underwater successfully, skirting the ship overhead. During the war of

1965, Pakistan reported it had sunk Vikrant. However, she was only undergoing

modification on a dry dock as there was a crack in a water drum of one of the

boilers.

In 1971, as India and Pakistan fought another war, Vikrant was

stationed off the Andaman & Nicobar Islands, along with frigates INS

Brahmaputra and INS Beas. “She was operated from Andaman & Nicobar as it

reduced the flying time to East Pakistan and gave the aircraft more time over

target. We sent out deceptive signals and the enemy was under the impression

that she was stationed at Visakhapatnam,” recalls an officer.

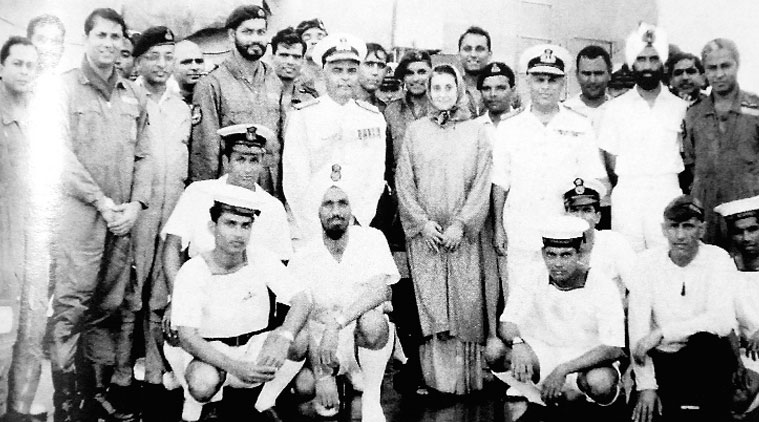

|

Indira Gandhi with the crew of the

ship that helped her win the 1971 war with Pakistan

|

On the morning of December 4, 1971,

Vikrant’s eight Sea Hawk aircraft launched an air raid on Cox’s Bazar in Dhaka

and the same evening, the air group struck Chittagong Harbour. Attacks such as

these cut off the escape route of the Pakistani Navy. “With their morale

destroyed, surrender was inevitable,” says I C Rao, vice-admiral (retd).

According to Naval officers, Vikrant launched more than 1,000 sorties in its

lifetime. It was decommissioned in 1997 and turned into a museum, but in 2012,

it was found to be unsafe. Earlier this year, it was brought to Lakribunder. A

brochure at the time of the decommissioning read, “Sail well Old Lady, sail

well. For we shall sail together again, when you and I meet on the jetty on the

other side of time.” India now has two warships; a third being built

indigenously is called ‘INS Vikrant’.

Source: Indian express. 30 November 2014